When your business or facility relies on continuous power, the hum of your commercial generator is more than just a sound—it's the heartbeat of your operations. But what happens when that rhythm falters? When your Generator Electrical System & Control Panel Repairs become an urgent priority, the stakes are incredibly high. From flickering displays to complete system shutdowns, electrical and control panel issues can bring critical functions to a grinding halt, threatening everything from data integrity to patient safety.

We're diving deep into the intricate world of generator electrical systems and control panels, offering you a comprehensive guide to understanding, diagnosing, and repairing these vital components. This isn't just about fixing a problem; it's about protecting your investment, ensuring regulatory compliance, and most importantly, maintaining an uninterrupted power supply that keeps your world running.

At a Glance: What You'll Learn

- Why timely repairs matter: Prevent escalating damage, extend lifespan, and avoid costly downtime.

- Key components: Understand the crucial roles of your generator's electrical system and control panel elements.

- Common failure points: Identify what often goes wrong, from frayed wires to unresponsive displays.

- The repair process: What to expect during a professional diagnostic and repair service.

- Preventative measures: How to minimize future electrical and control panel issues.

- When to call the pros: Recognizing the signs that demand expert intervention.

The Brains and Nerves: Unpacking Your Generator's Electrical System and Control Panel

Think of your commercial generator as a sophisticated machine with a powerful engine at its core. But what tells that engine when to start, how fast to run, and when to deliver power? That's the job of its electrical system and, more specifically, its control panel. This intricate network of wires, sensors, and electronic components acts as the generator's nervous system and brain, translating raw mechanical power into reliable electrical output.

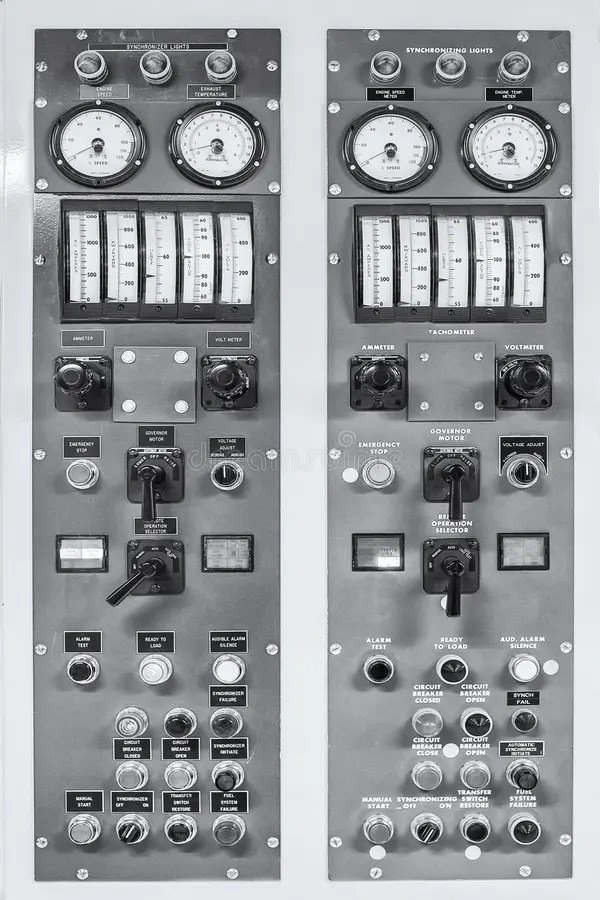

The electrical system encompasses everything from the starter motor that kicks the engine to life, to the alternator windings that generate electricity, and the wiring harnesses that transmit power and signals throughout the unit. The control panel, a highly specialized part of this system, is where all the monitoring, regulation, and safety functions converge. It houses microcontrollers, Automatic Voltage Regulators (AVRs), relays, sensors, and displays that give you a real-time snapshot of your generator's health and performance.

Why Electrical and Control Panel Health Is Non-Negotiable

For industries where even a momentary power disruption can have severe consequences—healthcare facilities, data centers, manufacturing plants, telecommunications hubs, and critical municipal services—a robust and reliable generator electrical system is paramount. It’s not just about having a backup; it’s about having a dependable backup. Issues with these components can manifest as anything from a "hard start" (difficulty getting the engine running) to a complete failure to transfer load, or erratic power output that could damage connected equipment. Ignoring these signs is like ignoring chest pains – it will only lead to more severe complications down the line.

Decoding the Fault Lines: Common Electrical and Control Panel Failures

Understanding where generator electrical system and control panel issues typically arise is the first step toward effective troubleshooting and repair. Many problems are predictable, stemming from wear and tear, environmental factors, or sudden electrical events.

The Control Panel: Where Intelligence Meets Vulnerability

Your control panel is a marvel of modern engineering, but it's also highly susceptible to several issues:

- Wear and Age: Like any electronic device, components within the control panel—microcontrollers, relays, and displays—degrade over time. Buttons might become unresponsive, screens might dim or pixelate, and internal circuits can simply wear out.

- Electrical Surges: Lightning strikes, grid fluctuations, or even internal short circuits can send damaging voltage spikes through the panel, frying sensitive electronics.

- Environmental Factors: Moisture ingress (from humidity, rain, or condensation) can cause corrosion and short circuits. Extreme temperatures can also stress components, leading to premature failure.

- Rodent Damage: A common, yet often overlooked, culprit. Rodents love to chew on wiring, creating short circuits or open circuits that lead to unpredictable behavior or complete panel failure.

- Software Glitches: Modern control panels run on firmware. Bugs, corruption during updates, or memory issues can cause erratic operation, false alarms, or system shutdowns.

Symptoms of a Failing Control Panel: Malfunctioning displays, persistent error messages, unresponsive buttons or switches, erratic generator behavior (e.g., unexpected shutdowns or starts), or a complete failure to operate the generator.

Wiring Harnesses: The Lifelines Under Threat

These bundles of wires are the unsung heroes, carrying power and critical signals between every component. Yet, they're constantly exposed to vibration, heat, and environmental stressors:

- Physical Damage: Abrasion, impacts, or—again—rodent activity can fray or sever wires. This leads to intermittent connections, short circuits, or complete signal loss.

- Corrosion: Moisture and chemical exposure can corrode terminals and wire strands, increasing resistance and hindering proper signal or power flow. This is particularly prevalent in outdoor or harsh industrial environments.

- Heat Damage: Excessive engine heat can degrade wire insulation, leading to shorts or open circuits.

Symptoms of Wiring Harness Issues: Intermittent power, flickering lights, frequent circuit breaker trips, components failing to activate, or visible signs of fraying, discoloration, or burning smells.

Battery Chargers: The Silent Guardian

Often overlooked until it's too late, the battery charger maintains the generator's starting battery at optimal levels. A dead battery means a non-starting generator, regardless of how healthy the engine or alternator is.

- Component Failure: Internal circuits can fail due to age, power surges, or manufacturing defects.

- Corrosion: Battery acid fumes can corrode charger terminals and internal components.

Symptoms of Charger Failure: Difficulty starting the generator (especially in an emergency), a perpetually low or overcharged starting battery, or visible damage/corrosion on the charger unit itself.

Alternator Windings, Rotors, and Stators: The Power Producers

These are the components within the generator end that actually produce electricity. Their health is directly linked to your power output:

- Heat Degradation: High operating temperatures, often due to improper ventilation or overloading, can degrade the insulation around the windings, leading to short circuits between turns or to the frame.

- Vibration and Mechanical Stress: Constant vibration can loosen windings, damage insulation, or cause mechanical wear on bearings, leading to electrical faults or structural damage.

- Electrical Overloads/Shorts: Sudden power demands or external short circuits can stress the windings beyond their limits.

Symptoms of Generator End Electrical Issues: Reduced power output (low voltage or current), overheating of the generator end, unusual noises (grinding, humming), or visible signs of charred insulation or damage. You might notice your facility struggling to power all its equipment during an outage, or perhaps the automatic transfer switch fails to switch loads due to insufficient power.

Starter Motor: The First Spark

The starter motor's job is simple but critical: crank the engine to get it running.

- Frequent Use/Wear: High-usage generators or those that experience frequent start-stop cycles will wear out starter motor components like brushes, solenoids, or gears more quickly.

- Electrical Issues: Weak battery, corroded terminals, or a faulty starter solenoid can prevent the motor from engaging.

Symptoms of Starter Motor Issues: Difficulty starting, slow cranking, grinding noises when attempting to start, or a complete failure to crank the engine.

Block Heaters: Cold Start Assurance

In colder climates, block heaters keep the engine block warm, making it easier for the generator to start and reducing wear.

- Heating Element Failure: The electrical heating element can burn out or become less efficient over time.

- Leakage: Seals can fail, leading to coolant leaks.

Symptoms of Block Heater Failure: Slow or difficult starting in cold weather, increased warm-up time, or visible coolant leaks around the heater unit.

The interconnectedness of these systems means a failure in one component often stresses others. For instance, a faulty battery charger might lead to a weak starter motor, which in turn might cause the generator to fail to start during a crucial power outage.

The Art of Restoration: How Generator Electrical System Repairs Work

When your generator shows signs of distress, a systematic approach to diagnosis and repair is crucial. This isn't a job for guesswork; it requires precision, specialized tools, and in-depth expertise.

Step 1: The Full Diagnostic Deep Dive

Every professional repair service begins with a comprehensive diagnostic evaluation. This isn't just about reading error codes; it's a multi-faceted investigation into the health of your entire system.

- Visual Inspections: Technicians meticulously examine wiring harnesses for fraying or corrosion, check for signs of rodent damage, and inspect the control panel for physical damage or moisture.

- Electrical Output Checks: Using advanced multimeters and oscilloscopes, technicians measure voltage, current, frequency, and waveform quality to pinpoint issues like low voltage, erratic output, or harmonic distortion from the generator end.

- Load Testing: This is a critical step. The generator is run under a simulated or actual load to verify its ability to perform under real-world conditions. This can reveal problems that only surface under stress, such as overheating windings or voltage drops.

- Fuel Quality Tests: While primarily a fuel system concern, fuel quality can indirectly impact electrical controls if sensors are affected.

- Control Panel Analysis: Advanced diagnostic software is used to interface with the control panel, pulling historical error logs, monitoring real-time sensor data, and testing individual relays and outputs. This helps identify microcontroller faults, sensor malfunctions, or software bugs.

- Component-Specific Testing: Individual components like starter motors, battery chargers, and block heaters are tested for proper function and electrical integrity.

Step 2: Pinpointing the Problem and Planning the Fix

Based on the diagnostic findings, a clear picture emerges. The technician will identify the root cause of the problem and recommend the necessary repairs. This might range from simple component replacements to more complex system overhauls.

Step 3: Executing the Repair

This is where expertise truly shines. Repairs are carried out using manufacturer-approved parts and best practices to ensure longevity and reliability.

- Component Replacement: Often, the most direct solution involves replacing faulty parts. This could be a new starter motor, a complete control panel replacement, fresh wiring harnesses, or a new battery charger.

- Winding Tests and Repair: For generator end issues, specialized equipment like a megohmmeter (megger) is used to test winding insulation. In some cases, minor winding repairs or re-insulation might be possible; in others, a complete stator or rotor replacement is necessary.

- Bearing Replacement: Worn bearings in the generator end or engine can cause vibrations that damage electrical components. Replacing these restores smooth operation.

- Control Panel Service and Reprogramming: Digital and analog control panels can often be serviced, involving component-level repairs (e.g., replacing a faulty relay or capacitor). Often, firmware updates or reprogramming of parameters (e.g., automatic transfer switch logic, voltage setpoints) are required to restore full functionality or upgrade capabilities.

- Fuel System Sensor and Pump Replacement: While a mechanical issue, faulty fuel injectors or fuel pumps can send incorrect signals to the control panel, leading to performance issues or error codes. Their replacement ensures the engine receives precise fuel delivery, allowing the electrical system to manage it effectively.

- Troubleshooting Intermittent Faults: These are often the most challenging. Technicians systematically trace electrical circuits, checking for loose connections, compromised insulation, or transient component failures that only appear under specific operating conditions.

- System Upgrades: Sometimes, repairs lead to opportunities for upgrades, such as installing more robust control panels or improving monitoring capabilities.

You can rely on comprehensive generator repair solutions to get your system back on track, ensuring every component from the engine to the electrical system is functioning optimally.

Step 4: Verification and Testing

Once repairs are complete, the generator undergoes rigorous re-testing. This includes another load test to confirm stable output and proper operation of all repaired electrical and control panel functions. This ensures that the problem is truly resolved and won't reappear as soon as the unit is needed.

The Cost of Inaction: Why Timely Electrical Repairs are Crucial

Delaying repairs to your generator's electrical system or control panel isn't just risky; it's financially hazardous. The initial malfunction is rarely the full story.

Preventing Further Damage

A compromised electrical system can act like a slow poison to your entire generator. For instance:

- A faulty AVR (Automatic Voltage Regulator) can cause voltage fluctuations that damage the generator's windings over time or even harm connected equipment.

- Frayed wiring can lead to short circuits, potentially causing fires or frying other sensitive electronic components in the control panel.

- Running a generator with a persistent electrical fault can strain the engine and alternator, leading to premature wear and tear on mechanical components that weren't initially affected.

Extending Generator Lifespan

Just like regular oil changes extend an engine's life, proactive electrical system and control panel repairs significantly prolong the operational lifespan of your entire generator. Addressing minor issues before they cascade into major failures ensures that the unit remains reliable for years, protecting your substantial investment.

Maintaining Compliance and Safety

Many industries have strict regulations regarding backup power systems. A malfunctioning generator, particularly one with electrical or control panel issues, might not pass inspections and could lead to fines, operational restrictions, or even pose significant safety risks. Electrical faults carry inherent dangers, including electrocution and fire. Timely repairs ensure the system operates safely for both personnel and equipment.

Avoiding Costly Downtime

This is perhaps the most critical consequence for commercial and industrial users. In sectors like healthcare, telecommunications, data centers, and manufacturing, downtime isn't just an inconvenience—it can be catastrophic.

- Healthcare: Loss of power can jeopardize patient care, compromise critical life-support systems, and halt essential operations.

- Data Centers: Even a brief outage can lead to data corruption, service interruptions, and massive financial losses.

- Manufacturing: Production lines stop, leading to lost output, wasted materials, and missed deadlines.

- Commercial Real Estate: Disrupts business operations for tenants, impacts security systems, and affects essential services like elevators and HVAC.

The cost of lost revenue, damaged reputation, and potential liability far outweighs the expense of prompt, professional repairs.

Keeping the Lights On: Proactive Maintenance and Expert Support

The best repair is often the one you never need. A robust preventive maintenance strategy is your first line of defense against electrical system and control panel failures.

The Power of Routine Service and Exercise

Industrial generators, especially critical standby units, demand consistent attention.

- Regular Service Intervals: Under normal operating conditions, servicing your industrial generator at least twice a year (typically every 3-6 months) is a baseline. For critical applications or harsh environments, quarterly service is a must. This includes not just fluid and filter changes, but comprehensive electrical checks, tightening connections, inspecting wiring, and testing control panel functionality.

- Generator Exercise: Running your generator regularly under a load (monthly for most, weekly for critical systems) is vital. This ensures that all components, particularly the electrical system and control panel, are cycled through their operational states. It prevents fuel system stagnation, lubricates engine parts, and verifies that the transfer switch and electrical components are ready to perform when needed. Many control panels can be programmed for automatic exercise cycles.

Recognizing the Red Flags

While routine maintenance catches many issues, stay vigilant for any changes in your generator's behavior:

- Unusual Noises or Smells: Grinding, buzzing, or burning odors can indicate electrical shorts or mechanical wear.

- Erratic Operation: Unexplained shutdowns, difficulty starting, or inconsistent power output.

- Control Panel Anomalies: Warning lights, error codes, unresponsive buttons, or dimming displays.

- Visible Damage: Frayed wires, corrosion, leaks, or physical damage to any component.

When to Call the Experts

Attempting complex electrical or control panel repairs without proper training and tools is incredibly dangerous and can cause further damage. If you observe any of the red flags, or if your generator simply isn't performing as expected, it's time to call in the professionals.

Specialized repair services offer:

- 24/7 Emergency Repairs: For sudden outages, expert technicians can be dispatched rapidly to diagnose and provide solutions, often including temporary fixes or rental generators to restore power immediately.

- Advanced Diagnostics: Leveraging specialized equipment and software that goes beyond basic troubleshooting.

- Certified Technicians: Experts trained on specific generator brands and models, ensuring repairs are done correctly and safely.

- Access to Genuine Parts: Using authentic replacement components guarantees compatibility and reliability.

- Rental Solutions: If a repair requires significant time, portable rental generators can seamlessly provide power, minimizing business interruption. This is especially useful during scheduled maintenance or extended overhauls.

- Scalable Expertise: Whether you manage a single standby unit or a large-scale installation up to and beyond 20 MW capacity, qualified teams can handle everything from engineering design and logistical planning to on-site installation, commissioning, and implementing advanced controls for synchronizing multiple generators.

Reputable providers, like Generator Source, often have field teams positioned strategically in key regions (e.g., Colorado, Florida, Texas, and surrounding states) with main facilities and regional service centers equipped for complete teardown, rebuild, and load testing capabilities. Mobile repair teams bring the expertise directly to your site for on-the-spot diagnostics and repairs.

Your Power, Securely On

Your commercial generator is more than just a machine; it's a critical asset that safeguards your operations, revenue, and reputation. The electrical system and control panel are its nerve center, demanding meticulous care and prompt attention when issues arise. By understanding the common failure points, embracing a proactive maintenance schedule, and knowing when to engage experienced professionals for Generator Electrical System & Control Panel Repairs, you ensure that your power remains consistently on, no matter what challenges come your way. Don't wait for a crisis to realize the value of a well-maintained, fully functional generator—invest in its reliability today.